High pressure water mist system

Introduction

Water Mist Principle

Water Mist is defined in NFPA 750 as a water spray for which the Dv0.99, for the flow-weighted cumulative volumetric distribution of water droplets, is less than 1000 microns at the minimum design operating pressure of the water mist nozzle. The water mist system works at a high-pressure to deliver water as a fine atomised mist. This mist is quickly converted into steam that smothers the fire and prevents further oxygen from reaching it. At the same time, the evaporation creates a significant cooling effect.

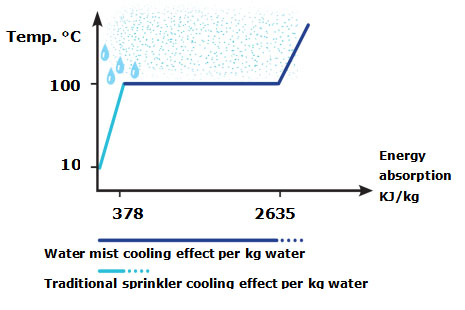

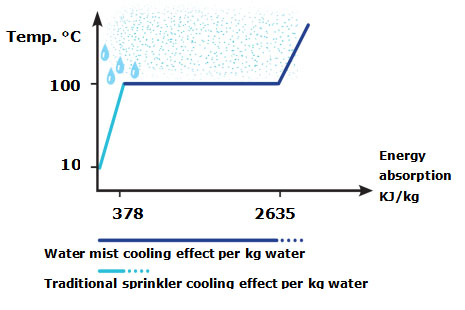

Water has excellent heat absorption properties absorbing 378 KJ/Kg. and 2257 KJ/Kg. to convert to steam, plus approximately 1700:1 expansion in doing so. In order to exploit these properties, the surface area of the water droplets must be optimised and their transit time (before hitting surfaces) maximised. In doing so, fire suppression of surface flaming fires can be achieved by a combination of

1. Heat extraction from the fire and fuel

2. Oxygen reduction by steam smothering at the flame front

3. Blocking of radiant heat transfer

4. Cooling of combustion gases

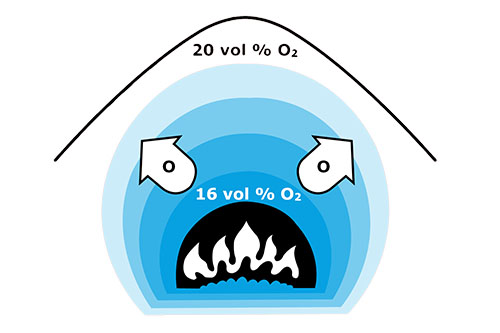

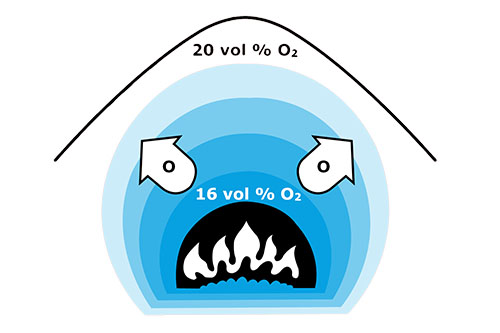

For a fire to survive, it relies on the presence of the three elements of the ‘fire triangle’: oxygen, heat and combustible material. The removal of any one of these elements will extinguish a fire. A high-pressure water mist system goes further. It attacks two elements of the fire triangle: oxygen and heat.

The very small droplets in a high-pressure water mist system quickly absorb so much energy that the droplets evaporate and transform from water to steam, because of the high surface area relative to the small mass of water. This means that each droplet will expand approximately 1700 times, when getting close to the combustible material, whereby oxygen and combustible gasses will be displaced from the fire, meaning that the combusting process will increasingly lack oxygen.

To fight a fire, a traditional sprinkler system spreads water droplets over a given area, which absorbs heat to cool the room. Due to their large size and relatively small surface, the main part of the droplets will not absorb enough energy to evaporate, and they quickly fall to the floor as water. The result is a limited cooling effect.

By contrast, high-pressure water mist consists of very small droplets, which fall more slowly. Water mist droplets have a large surface area relative to their mass and, during their slow descent towards the floor, they absorb much more energy. A great amount of the water will follow the saturation line and evaporate, meaning that water mist absorbs much more energy from the surroundings and thus the fire.

That’s why high-pressure water mist cools more efficiently per litre of water: up to seven times better than can be obtained with one litre of water used in a traditional sprinkler system.

Introduction

Water Mist Principle

Water Mist is defined in NFPA 750 as a water spray for which the Dv0.99, for the flow-weighted cumulative volumetric distribution of water droplets, is less than 1000 microns at the minimum design operating pressure of the water mist nozzle. The water mist system works at a high-pressure to deliver water as a fine atomised mist. This mist is quickly converted into steam that smothers the fire and prevents further oxygen from reaching it. At the same time, the evaporation creates a significant cooling effect.

Water has excellent heat absorption properties absorbing 378 KJ/Kg. and 2257 KJ/Kg. to convert to steam, plus approximately 1700:1 expansion in doing so. In order to exploit these properties, the surface area of the water droplets must be optimised and their transit time (before hitting surfaces) maximised. In doing so, fire suppression of surface flaming fires can be achieved by a combination of

1. Heat extraction from the fire and fuel

2. Oxygen reduction by steam smothering at the flame front

3. Blocking of radiant heat transfer

4. Cooling of combustion gases

For a fire to survive, it relies on the presence of the three elements of the ‘fire triangle’: oxygen, heat and combustible material. The removal of any one of these elements will extinguish a fire. A high-pressure water mist system goes further. It attacks two elements of the fire triangle: oxygen and heat.

The very small droplets in a high-pressure water mist system quickly absorb so much energy that the droplets evaporate and transform from water to steam, because of the high surface area relative to the small mass of water. This means that each droplet will expand approximately 1700 times, when getting close to the combustible material, whereby oxygen and combustible gasses will be displaced from the fire, meaning that the combusting process will increasingly lack oxygen.

To fight a fire, a traditional sprinkler system spreads water droplets over a given area, which absorbs heat to cool the room. Due to their large size and relatively small surface, the main part of the droplets will not absorb enough energy to evaporate, and they quickly fall to the floor as water. The result is a limited cooling effect.

By contrast, high-pressure water mist consists of very small droplets, which fall more slowly. Water mist droplets have a large surface area relative to their mass and, during their slow descent towards the floor, they absorb much more energy. A great amount of the water will follow the saturation line and evaporate, meaning that water mist absorbs much more energy from the surroundings and thus the fire.

That’s why high-pressure water mist cools more efficiently per litre of water: up to seven times better than can be obtained with one litre of water used in a traditional sprinkler system.

1.3 High Pressure Water Mist System Introduction

The high pressure water mist system is a unique firefighting system. Water is forced through micro nozzles at very high pressure to create a water mist with the most effective firefighting drop size distribution. The extinguishing effects provide optimum protection by cooling, due to heat absorption, and inerting due to the expansion of water by approximately 1,700 times when it evaporates.

1.3.1 The key component

Specially-designed water mist nozzles

The high pressure water mist nozzles are based on the technique of the unique Micro nozzles. Due to their special form, the water gains strong rotary motion in the swirl chamber and is extremely quickly transformed into a water mist that is jetted into the fire at great speed. The large spray angle and the spray pattern of micro nozzles enable a high spacing.

The droplets formed in the nozzle heads are created using between 100-120 bars of pressure.

After a series of intensive fire tests as well as mechanical and material tests, the nozzles are specially made for high-pressure water mist. All tests are carried out by independent laboratories so that even the very strict demands for offshore are fulfilled.

Pump design

Intensive research has led to the creation of the world’s lightest and most compact high-pressure pump. Pumps are multi-axial piston pumps made in corrosion resistant stainless steel. The unique design uses water as a lubricant, meaning that routine servicing and replacing lubricants are not needed. The pump is protected by international patents and is widely used in many different segments. The pumps offer up to 95% energy efficiency and very low pulsation, thus reducing noise.

Highly corrosion-proof valves

High-pressure valves are made from stainless steel and are highly corrosion-proof and dirt resistant. The manifold block design makes the valves very compact, which makes them very easy to install and operate.

1.3.2 Benefits of high pressure water mist system

The benefits of the high pressure water mist system are immense. Controlling/ Putting out the fire in seconds, without using any chemical additives and with minimal consumption of water and close to no water damage, it is one of the most environmentally-friendly and efficient firefighting systems available, and is totally safe for human beings.

Minimum use of water

• Limited water damage

• Minimal damage in the unlikely event of accidental activation

• Less need for a pre-action system

• An advantage where there is an obligation to catch water

• A reservoir is rarely needed

• Local protection giving you faster fire fighting

• Less downtime due to low fire and water damage

• Reduced risk of losing market shares, as production is quickly up and running again

• Efficient – also for fighting oil fires

• Lower water supply bills or taxes

Small stainless steel pipes

• Easy to install

• Easy to handle

• Maintenance free

• Attractive design for easier incorporation

• High quality

• High durability

• Cost-effective at piece-work

• Press fitting for quick installation

• Easy to find room for pipes

• Easy to retrofit

• Easy to bend

• Few fittings needed

Nozzles

• Cooling ability enables installation of a glass window in the fire door

• High spacing

• Few nozzles – architecturally attractive

• Efficient cooling

• Window cooling – enables purchase of cheaper glass

• Short installation time

• Aesthetic design

1.3.3 Standards

1. NFPA 750 – edition 2010

2 SYSTEM description and components

2.1 Introduction

The HPWM system will consist of a number of nozzles connected by stainless steel piping to a high-pressure water source (pump units).

2.2 Nozzles

HPWM nozzles are precision engineered devices, designed depending on the system application to deliver a water mist discharge in a form that ensures fire suppression, control or extinguishment.

2.3 Section valves – Open nozzle system

Section valves are supplied to the water mist firefighting system in order to separate the individual fire sections.

Section valves manufactured of stainless steel for each of the sections to be protected are supplied for installation into the pipe system. The section valve is normally closed and opened when fire extinguishing system operates.

A section valve arrangement may be grouped together on a common manifold, and then the individual piping to the respective nozzles is installed. The section valves may also be supplied loose for installation into the pipe system at suitable locations.

The section valves should be located outside the protected rooms if not other has been dictated by standards, national rules or authorities.

The section valves sizing is based on each of the individual sections design capacity.

The system section valves are supplied as an electrically operated motorized valve. Motorised operated section valves normally require a 230 VAC signal for operation.

The valve is pre-assembled along with a pressure switch and isolation valves. The option to monitor the isolation valves is also available along with other variants.

2.4 Pump unit

Pump unit will typical operate between 100 bar and 140 bar with single pump flow rates rang 100l/min. Pump systems can utilise one or more pump units connected through a manifold to the water mist system to meet the system design requirements.

2.4.1 Electrical pumps

When the system is activated, only one pump will be started. For systems incorporating more than one pump, the pumps will be started sequentially. Should the flow increase due to the opening of more nozzles; the additional pump(s) will automatically start. Only as many pumps as are necessary to keep the flow and operating pressure constant with the system design will operate. The high pressure water mist system remains activated until qualified staff or the fire brigade manually shut off the system.

Standard pump unit

The pump unit is a single combined skid mounted package made up of the following assemblies:

| Filter unit | Buffer tank (Depend on the inlet pressure and pump type) |

| Tank overflow and level measurement | Tank inlet |

| Return pipe (can with advantage be leaded to outlet) | Inlet manifold |

| Suction line manifold | HP pump unit(s) |

| Electric motor (s) | Pressure manifold |

| Pilot pump | Control panel |

2.4.2 Pump unit panel

The motor starter control panel is as standard mounted at the pump unit.

Common power supply as standard: 3x400V, 50 Hz.

The pump(s) are direct on line started as standard. Start-delta starting, soft starting and frequency converter starting can be provided as options if reduced starting current is needed.

If the pump unit consists of more than one pump, a time control for gradually coupling of the pumps has been introduced to obtain a minimum of starting load.

The control panel has a RAL 7032 standard finish with an ingress protection rating of IP54.

Starting of the pumps is achieved as follows:

Dry systems– From a volt-free signal contact provided at the fire detection system control panel.

Wet systems – From a drop in pressure in the system, monitored by the pump unit motor control panel.

Pre-action system – Need indications from both a drop in air pressure in the system and a volt-free signal contact provided at the fire detection system control panel.

2.5 Information, tables and drawings

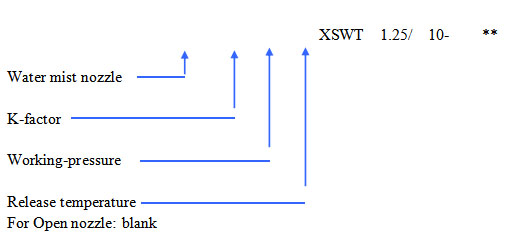

2.5.1 Nozzle

Special care must be taken to avoid obstructions when designing water mist systems, especially when using low flow, small droplet size nozzles as their performance will be adversely affected by obstructions. This is largely because the flux density is achieved (with these nozzles) by the turbulent air within the room allowing the mist to spread evenly within the space - if an obstruction is present the mist will not be able to achieve its flux density within the room as it will turn into larger drops when it condenses on the obstruction and drip rather than spreading evenly within the space.

The size and distance to obstructions depend of the nozzle type. The information can be found on the data sheets for the specific nozzle.

Fig 2.1 Nozzle

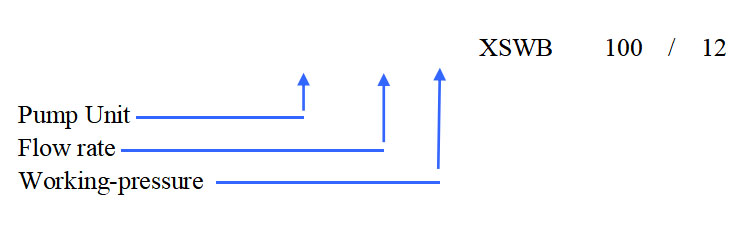

2.5.2 Pump unit

|

Type |

Output l/min |

Power KW |

Standard pump unit with control panel L x W x H mm |

Oulet mm |

Pump unit weight kg approx |

|

XSWB 100/12 |

100 |

30 |

1960×430×1600 |

Ø42 |

1200 |

|

XSWB 200/12 |

200 |

60 |

2360×830×1600 |

Ø42 |

1380 |

|

XSWB 300/12 |

300 |

90 |

2360×830×1800 |

Ø42 |

1560 |

|

XSWB 400/12 |

400 |

120 |

2760×1120×1950 |

Ø60 |

1800 |

|

XSWB 500/12 |

500 |

150 |

2760×1120×1950 |

Ø60 |

1980 |

|

XSWB 600/12 |

600 |

180 |

3160×1230×1950 |

Ø60 |

2160 |

|

XSWB 700/12 |

700 |

210 |

3160×1230×1950 |

Ø60 |

2340 |

Power: 3 x 400VAC 50Hz 1480 rpm.

Fig 2.2 Pump Unit

2.5.3 Standard valve assemblies

Standard valve assemblies are indicated below Fig 3.3.

This valve assembly is recommended for multi-section systems fed from the same water supply. This configuration will allow other sections to remain operable whilst maintenance is carried out on one section.

Fig 2.3 – Standard section valve assembly – Dry Pipe System with Open Nozzles